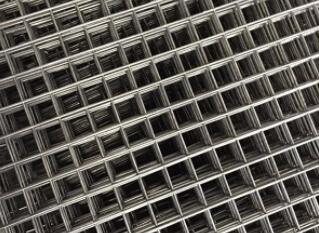

Stainless steel welding mesh has strong anti-corrosion and anti-oxidation characteristics. Used for machinery protection, industry, agriculture, construction, etc. Stainless steel wire welding mesh selection of high quality stainless steel wire, through the precision automatic machine welding, the product net surface smooth, solid structure, strong integrity, with strong corrosion resistance.

Nitric acid point test of stainless steel welding mesh. A notable feature of stainless steel tubes is their inherent corrosion resistance to concentrated and dilute nitric acid. This property allows it to be easily distinguished from most other metals or alloys. However, high carbon 420 and 440 steels are slightly corroded in nitric acid point test, and non-ferrous metals will be corroded immediately when they encounter concentrated nitric acid. Dilute nitric acid is strongly corrosive to carbon steel.

The experiment of sulfuric acid immersion stainless steel wire mesh. This experiment was used to distinguish 302 and 304 from 316 and 317. The cut edge of the sample is fine ground and then soaked in nitric acid with a volume concentration of 20-30% and a temperature of 60-66 ℃ for washing and passivation for half an hour. The sulfuric acid test solvent with a volume concentration of 10% is heated to 71 ℃. When 302 and 304 first enter this solution, they are rapidly corroded and produce samples with known components for approximate comparison. In this way, the experiment can be more accurate.

Copper sulfate spot test for stainless steel welding mesh. The copper sulfate point test is the simplest and most convenient way to quickly distinguish ordinary carbon steels from all types of stainless steels. The concentration of the copper sulfate solution used is 5~10%. Before the point test, the test area should be thoroughly cleaned of grease or various impurities, and a small area should be polished with a soft cloth, and then a drop bottle should be used to drop copper sulfate solution into the cleaned area. Ordinary carbon steel or iron forms a surface layer of copper in a matter of seconds, while the surface of stainless steel does not deposit copper or show copper color.

Translation software translation, if there is any error please forgive.

Post time: 27-05-21